Loading...

Loading...

Meet us at the Paris Packaging Week 2023

You can meet us on January 25 and 26 at the Paris Packaging Week 2023. Our team will be present on the Comité Français des Aérosols (French Aerosol Committee or CFA) stand.

Meet us at the Paris Packaging Week 2022

Paris Packaging Week 2022

On June 29 and 30, 2022, the LEREM will be present at the stand of the Comité Français des Aérosols (French Aerosol Committee or CFA) at the Paris Packaging Week

General information on impedancemetry

IMPEDANCEMETRY IS A SCIENCE

A brief history of impedancemetry

The first tests relating to impedancemetry date back to Georg Simon OHM (1788-1854), a famous physicist, who established the fundamental relationships between current, voltage and electrical resistance. This science has become popular in recent years, particularly in the medical or paramedical fields. However, it should be noted that this science has been implemented in packaging studies since the 80’s. LEREM, for its part, has been practicing these studies since early 90’s.

Imagine that you can materialize a set of elements through a mathematical model and that these elements can give you physical quantities that you can study in absolute way but also in a relative way. For example, how they evolve over time…

This is what happens with modern person scales, which can read your muscle mass index in addition to your fat mass index, or even from one measurement to another can read how your diet changes your muscle mass…

It is one of many examples of impedance measurement applications. The popularized results of these measurements have gone through mathematical modelling. The mathematical models were calibrated based on the results of measurements of very weak and very precise electrical signals at different frequencies. These results were then used to represent your body in an equivalent electrical model of an RLC circuit (resistive, inductive, capacitive).

USAGE IN OUR FIELD

How can we now apply this science to metal packaging?

It will be done the same way as the bathroom scale, by applying weak electrical signals of great precision at different frequencies to the packaging.

We will seek, depending on the results, to create an equivalent RLC model. We will not try to find the packaging muscle mass but try to find a combination of things. That combination is made of internal coating, substrate and filled formula that present a mathematical model showing a high resistance and a very low capacity. What’s more, the measurements will be repeated at regular intervals so it can confirm, or not the stability of the results over time.

These measurements can only be applied if the packaged formula is sufficiently conductive. Certain formulas are not conductive enough and therefore do not allow studies by impedancemetry.

Evaluating the conductivity of formulas can be done easily by using a conductivity meter. Weak signal generators called potentiostat are also intended to go into safety mode if the formula is not compatible with the means of measurement. Note that these studies cannot replace storage compatibility studies. This is a reliable method of knowing more quickly what will not be compatible at the end. This is not a substitute for storage compatibility testing.

In addition, equipment’s and systems for processing measurements have evolved. Regarding this point, LEREM will be equipped with brand new state of the art equipment from December 2021. It will be covered in a future article.

With more than thirty years’ experience in this field and equipped with state-of-the-art equipment, LEREM remains at your disposal to carry out compatibility studies containing content using impedancemetry.

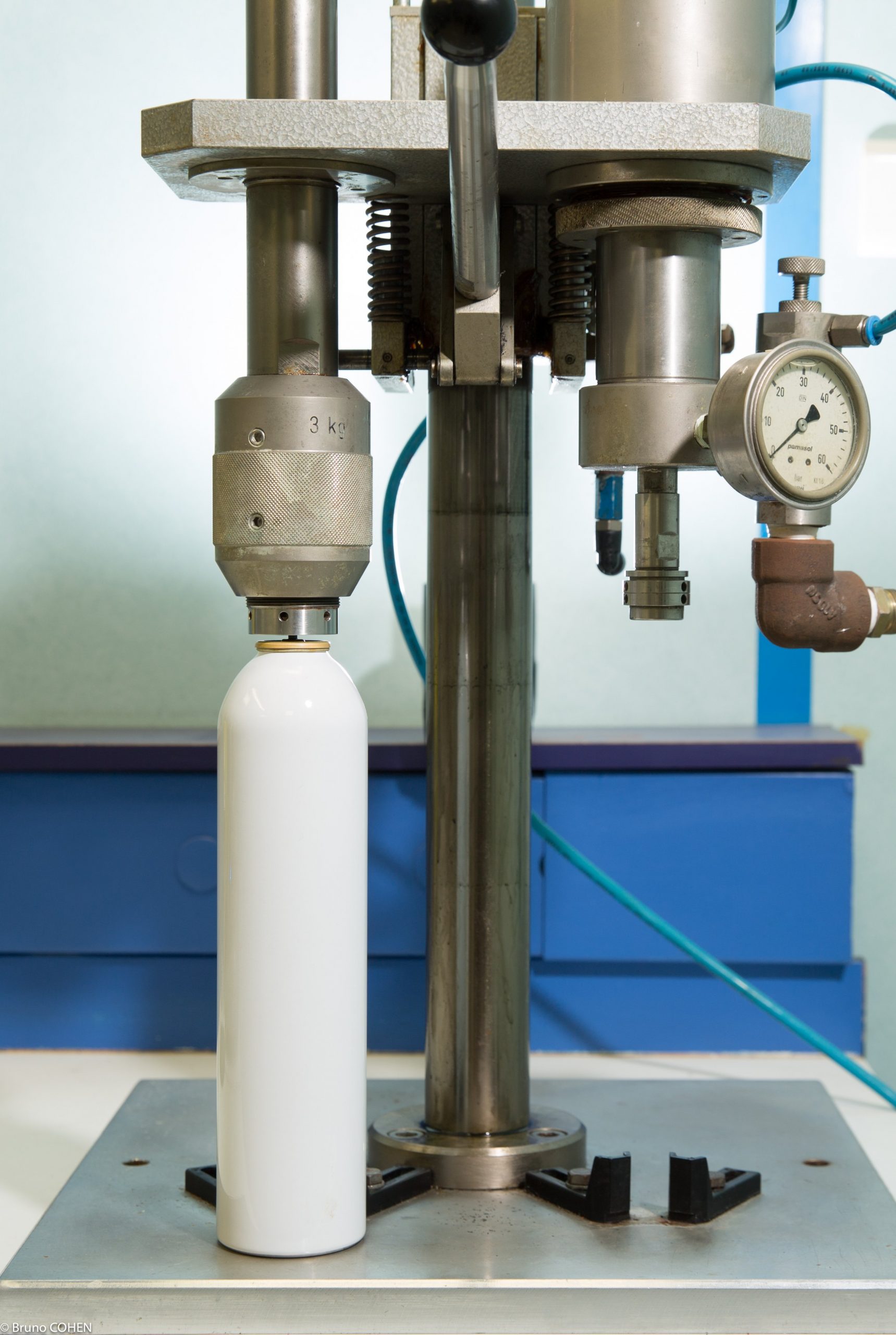

Studies on aerosol dispensers

Aerosol dispensers

Working with the primary goal of preventing technical problems with new and existing products to ensure the safety of the aerosol dispensers industry.

Aerosol dispensers are the most technical packaging available.

All the technical details that need to be controlled, in a very large industrial supply chain, must be realised so that, in the end, users can simply press the actuator of an aerosol can and the product is stored and dispensed correctly.

First, it is necessary to ensure that the aerosol dispenser as a form of packaging is perfectly safe and remains stable over time. Stability of the packaged formula and stability of the integrity of the packaging. For cosmetic products, we often talk about guaranteeing a product for a period of 3 years.

Second, all of this must be guaranteed on a mass production scale. It is estimated that in 2019, 15.5 billion aerosol dispensers were produced worldwide, of which 5.5 billion were produced in Europe.

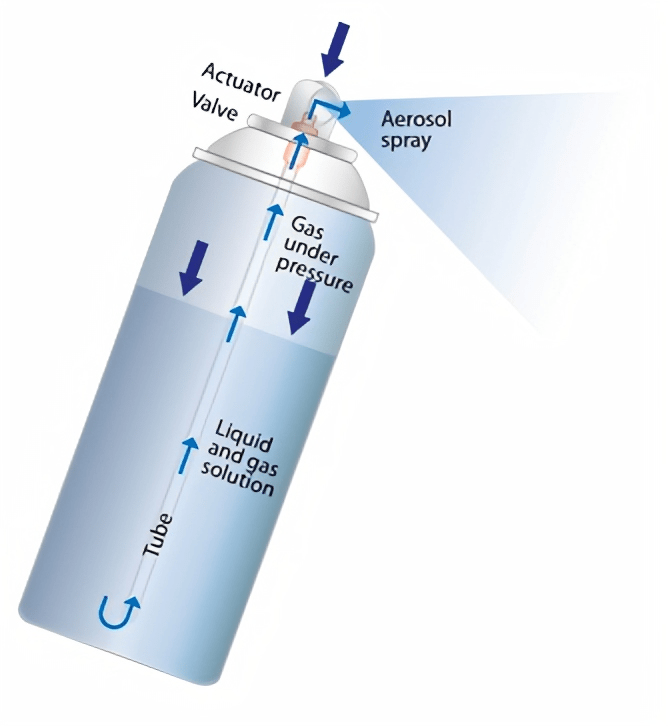

Composition of an aerosol dispenser

To make an aerosol dispenser, you need to master a formula, a propellant gas, a can, a valve, an actuator.

It is also necessary to master the filling process, the sealing parameters, i.e. the valve-Can assembly, the valve gasket compression and the Clinching specification, not forgetting all the filling parameters.

All of this works thanks to defined specifications, norms and standards, but also thanks to specifications safety margins that this industry has set for itself for decades.

LEREM’s expertise

There are not many places of expertise able to synthesise all these constraints. LEREM tries to do this as well as possible, thanks to the means at its disposal.

These various means are :

- Testing or stressing

- Filling

- Accelerated ageing tests by impedance measurement

- Storage chambers from 0 to 50°C

- Standard or customised flammability testing facilities for comparison purposes.

- Virtually all the precision measurement equipment required for aerosol dispensers’ assessments :

- Weight +/- 0.003g

- Pressure +/- 0.01 bar

- Temperature +/- 1°C

- Dimensional +/- 0,01 mm

- All the adapted cutting equipment

- The possibility to carry out resin studies

- Software for measuring crimping dimensions

- Vision system to observe details of valve-housing assemblies.

- Spray pattern measurement

- Clogging tests

- Laser particle size measurement of spray particles – Malvern Spraytech 2000.

- By the fact that LEREM has a recognised level of expertise and years of experience in this field.

- Its knowledge of aerosol dispensers’ industry supply chain and its network within this industry.

- Its close relationship with CFA: French Aerosol Association and their agreement established in 2021 for the next few years.

- By the fact that it is an association of public utility, which guarantees its discretion, objectivity, and independence.

More details about this subject on the dedicated page.

LEREM represents the industry and participates to fundamental studies

- The ECORBIO project, which aims to study the corrosion behaviour of piping with heat transfer fluids for the biorefinery circuits of the future using impedance measurement. In conjunction with INERIS, UTC, CETIM, UPJV.

- MPE (Metal packaging Europe) working group and the compatibility studies contained in the passivation processes for tinplate, which by 2027 should make it possible to use only chromium VI-free passivated tinplate. In the field of aerosol dispensers, this concerns tinplate can and valve mounting cups.

- The GDA (Gesamtverband der Aluminiumindustrie) supply chain meeting and the many questions raised by the use of alternative coatings to phenolic epoxy coatings. In the field of aerosol dispensers, this concerns aluminium aerosol cans.

- Various in-depth studies on existing aerosol dispensers’ flammability results, some of them linked to INERIS, which tend towards new gases development.

- The OLIGO project – a very recent ANR study on the NIAS for new internal coating generation in conjunction with LABERCA and INRAE.

- Standards at national level at AFNOR (Commission de Normalisation AFNOR/H08F CN8 Emballages), at European level CEN (TC261/SC5 emballage métallique), at international level ISO TC52 (light gauge metal containers).

- Accreditation of LEREM by the Ministry of Ecological Transition (DGPR) with regard to transport of hazardous materials.

- Parc industriel Européen

- Les marches de l’Oise

- Laboratoire LEREM

- 100 rue Louis BLANC

- 60160 Montataire (France)

- Phone : 03 44 28 56 30

- Cellphone : 06 37 05 21 94

- Email address: laboratoire@lerem.org

New REACH and CLP informations

In collaboration with the French Aerosol Committee, here is a summary of the points addressed by the french national regulatory assistance service. The new REACH and CLP informations are available in detail in a newsletter available for download at the end of this article.

New REACH informations

Restrictions

- RAC and SEAC advice: Restriction of lead in buckshot, shooting bullets and fishing tackle

- Call for contribution on 1,4-dioxane

SVHC Futures

- Public consultation

Evaluation

- CoRAP: 58 substances for 2021-2023

- Registrants: get ready to comment on the draft decisions about substance assessment (CoRAP 2020)

Registration

- PBT substances and applicable methods of analysis

SCIP database

- Available webinar materials

New CLP informations

Harmonized classification and labeling

- Ongoing public consultations

- RAC Opinion

Poison control center declarations

- Update of the guide Annnex VIII

ECHA

Integrated regulatory strategy

- “Mapping of the chemical universe” progress

POP

- Public consultation: Pentachlorophenol

AGENDA

The new REACH and CLP informations are available in the attached document.

Aerosol Dispensing Forum

The LEREM attended to Aerosol Dispensing Forum (29th and 30th of January 2020)